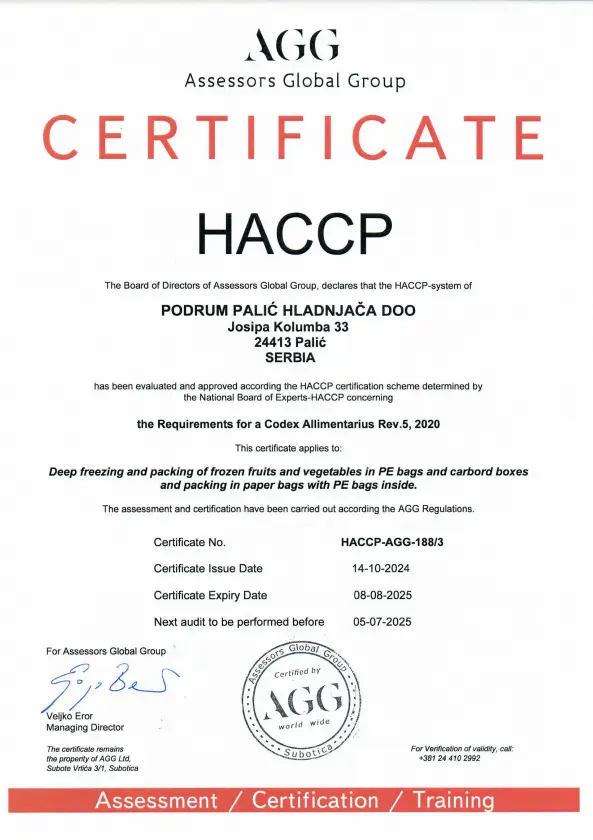

FSSC 22000 & HACCP

Optical sorting

Get paid quickly & spend yourearnings hassle-free.

Packaging of product

Get paid quickly & spend yourearnings hassle-free.

8 chambers

Get paid quickly & spend yourearnings hassle-free.

Podrum Palić cold store has a total processing capacity of 7.000 tons. Annual production of IQF sour cherry is 2.000 tons and 5.000 tons of IQF pepper. The cold store has a total storage capacity of 6.000 tons.

Packaging of product is done with the most modern methods and equipment such as: automatic scale, metal detector and two optical sorting machines (one before and one after freezing tunnel).

Packaging of product is done with the most modern methods and equipment such as: automatic scale, metal detector and two optical sorting machines (one before and one after freezing tunnel).

IQF product is stacked on EUR pallets in a chamber at optimal temperatures from -18 ° C to - 24 ° C until delivery.

The entire production process is automated and starts with the lines for fruit reception, washing, sorting, calibration and freezing. The optimal freezing capacity is 5 t/h, and production process is performed with machines by internationally recognized manufacturers.